ASTM A572 S235jr 50-сынып 150X150 W30X132 кең фланецті Ipe 270 Ipe 300 Heb 260 Hea 200 құрылыс H арқалығы

Өнімнің егжей-тегжейі

Ыстықтай жайылған кең фланецті болат арқалықтарW-тәрізді немесе H-тәрізді сәулелер деп те аталады, олар құрылыс және құрылымдық инженерияда кеңінен қолданылады. Олар кең фланецтерімен және түзу торымен сипатталады, бұл оларды ұзақ қашықтықта ауыр жүктемелерді көтеруге жарамды етеді.

Міне, кейбір типтік мәліметтерW фланецті A992 арқалықтары:

Өлшемдері:W-тәрізді сәулелертереңдігімен (дюйммен) және футына шаққандағы салмағымен (фунтпен) көрсетілген әртүрлі стандартты өлшемдерде қолжетімді, мысалы, W10x22 немесе W12x35.

Материал: Бұл арқалықтар әдетте көміртекті болаттан жасалады және ыстықтай илемдеу процесі арқылы өндіріледі, бұл болат дайындаманы жоғары температураға дейін қыздыруды және қажетті пішін мен өлшемдерге жету үшін оны бірқатар роликтер арқылы өткізуді қамтиды.

Қолданылуы: W-тәрізді арқалықтар беріктігі мен жүк көтергіштігіне байланысты ғимараттарда, көпірлерде және басқа да ірі құрылымдарда құрылымдық тірек ретінде кеңінен қолданылады.

Қасиеттері: Американдық стандартты W фланеці A992 жоғары беріктікке және тамаша жүк көтеру қабілетіне ие, бұл оларды әртүрлі құрылымдық қолданбаларда қолдануға жарамды етеді.

| ӨНІМ АТАУЫ | Q235 ЫСТЫҚ ЖАЙЫЛҒАН БОЛАТW фланецті H арқалықҚҰРЫЛЫМДЫҚ БОЛАТ H ПІШІНДІ БАРАҚТАР |

| БОЛАТ СЫНЫПЫ | A36, Q235, Q195, SS400, ST37-2 |

| БОЛАТ H БАРАҚ СТАНДАРТЫ | GB, ASTM, AISI, EN, JIS |

| БОЛАТ H БАРАҚ ҰЗЫНДЫҒЫ | 5.8-12M НЕМЕСЕ КЛИЕНТТІҢ ТАЛАПЫНА СӘЙКЕС |

| ТЕХНОЛОГИЯ | ЫСТЫҚ ПРОКАТТАЛҒАН НЕМЕСЕ ДӘНЕКЕРЛЕГЕН |

| ҚОЛДАНЫЛУЫ | ӘРТҮРЛІ ҒИМАРА ҚҰРЫЛЫМДАРЫНДА ЖӘНЕ ИНЖЕНЕРЛІК ҚҰРЫЛЫМДАРДА КЕҢІНЕН ҚОЛДАНЫЛАДЫ 1) БӨРЕУК, КӨПІРЛЕР, ҚҰРЫЛЫС, БАЙЛАНЫС МҰНАРАСЫ, КЕМЕ. 2) Беріліс мұнарасы, реакция мұнарасы, қойма тауарларының сөрелері және т.б. 3) КӨТЕРУ-ТАСУ МАШИНАЛАРЫ, АУЫЛ ШАРУАШЫЛЫҒЫ МАШИНАЛАРЫН ЖАСАУ 4) Өнеркәсіптік пеш 5) КОНТЕЙНЕР РАМАСЫ |

| ТҮПНҰСҚА | ҚЫТАЙ |

| БЕТТІК ӨҢДЕУ | ҚАРА НЕМЕСЕ ГАЛЬВАНИЗДЕЛГЕН |

| ПАКЕТ | КӨПТЕ НЕМЕСЕ БҮРШЕКТЕ |

| MOQ | 10 MT |

| ЖЕТКІЗУ УАҚЫТЫ | САЛЫМ САЛЫНҒАННАН КЕЙІН 10-30 КҮН |

| ТЕКСЕРУ | ISO9001:2000, BV, SGS және INTERTEK |

| Дивис ибн (тереңдік x idth | Бірлік Салмақ кг/м) | Сандард секциялық Өлшемі (мм) | Бөлімдік Аудан см² | ||||

| W | H | B | 1 | 2 | r | A | |

| HP8x8 | 53.5 | 203.7 | 207.1 | 11.3 | 11.3 | 10.2 | 68.16 |

| HP10x10 | 62.6 | 246.4 | 255.9 | 10.5 | 10.7 | t2.7 | 70.77 |

| 85.3 | 253.7 | 259.7 | 14.4 | 14.4 | 127 | 108.6 | |

| HP12x12 | 78.3 | 2992 | 305.9 | 11.0 | 11.0 | 15.2 | 99.77 |

| 93.4 | 303.3 | 308.0 | 13.1 | 13.1 | 15.2 | 119.0 | |

| 111 | 308.1 | 310.3 | 15.4 | 15.5 | 15.2 | 140.8 | |

| 125 | 311.9 | 312.3 | 17.4 | 17.4 | 15.2 | 158.9 | |

| HP14x14% | 108.0 | 345.7 | 370.5 | 12.8 | t2.8 | 15.2 | 137.8 |

| 132.0 | 351.3 | 373.3 | 15.6 | 15.6 | 15.2 | 168.4 | |

| 152.0 | 355.9 | 375.5 | 17.9 | 17.9 | 15.2 | 193.7 | |

| 174.0 | 360.9 | 378.1 | 20.4 | 20.4 | 15.2 | 221.5 | |

Ерекше өзгешеліктері

Қолданбалардағы әмбебаптылық:

Маңызды артықшылықтарының біріH сәулесіҚадалар құрылыс индустриясында кең ауқымды қолданбаларға жарамды ететін ерекше әмбебаптығымен ерекшеленеді. Керемет жүк көтергіштігінің арқасында бұл арқалықтар көпірлер, ғимараттар, қоймалар және басқа да ірі құрылыстар салуда кеңінен қолданылады.H пішінді болат арқалықтарсалмақты тиімді бөлуге мүмкіндік береді, ауыр жүктемелер кезінде салбырау немесе деформация қаупін азайтады.

Беріктігі және төзімділігі:

Ауыр жүктемелерді көтеруге келгенде, H-арқалық қадасы бәсекелестікте сөзсіз ерекшеленеді. Құрылымдық болаттан жасалған H-арқалық керемет беріктік қасиеттерін көрсетеді, бұл оны жүк көтергіштігі өте маңызды жобалар үшін тамаша таңдау етеді. Сонымен қатар, өндіріс процесінде ыстықтай илектелген болатты пайдалану бұл арқалықтардың жалпы беріктігі мен серпімділігін арттырады, бұл оларды майысуға, бұралуға және коррозияға өте төзімді етеді.

Дизайн икемділігі:

H Beam Pile-дің тағы бір назар аударарлық аспектісі - сәулетшілер мен инженерлерге инновациялық және эстетикалық тұрғыдан жағымды құрылымдар жасауға мүмкіндік беретін оның ішкі дизайн икемділігі.H-тәрізді профильбағандар, арқалықтар және тіректерді қоса алғанда, басқа құрылымдық элементтерге оңай қосылуға мүмкіндік береді, бұл шексіз жобалау мүмкіндіктерін береді. Сонымен қатар, әртүрлі өлшемдер мен салмақтардың болуы H-арқалықтарды нақты жоба талаптарына сәйкес келтіруге мүмкіндік береді.

Үнемді шешім:

Ерекше беріктігі мен дизайн икемділігінен басқа, H Beam Pile құрылыс жобалары үшін тартымды шешім болып табылатын шығындарды үнемдеуді де ұсынады. Бұл арқалықтарды стандартталған өндіріс процесі мен кең таралған қолжетімділіктің арқасында бәсекеге қабілетті бағамен сатып алуға болады. Сонымен қатар, H арқалықтарының беріктігі мен ұзақ мерзімділігі құрылымның қызмет ету мерзімі ішінде техникалық қызмет көрсету және ауыстыру тұрғысынан шығындарды үнемдеуге әкеледі.

Қолданба

H секциялы арқалықтардың қолданылуы:

Көп қырлылығыH секциялы арқалықтарОларды көптеген құрылыс жобаларында алмастырылмайтын етеді. H секциялы арқалықтар көпірлер құрылысында негізгі құрылымдық элементтер ретінде қызмет етеді, берік және берік аралықтардың негізін қамтамасыз етеді. Олардың ауыр жүктемелерге төтеп беру және бүйірлік күштерге қарсы тұру қабілеті оларды биік ғимараттар үшін өте қолайлы етеді, тұрақтылықты қамтамасыз етеді және үлкен еден саңылауларын орналастырады. Сонымен қатар, H секциялы арқалықтар өнеркәсіптік ортада қолданылады, ауыр техниканы қолдайды және кең көлемді көтеріңкі сақтау орнын қамтамасыз етеді.

H секциялы арқалықтар кеме жасау өнеркәсібінде де кеңінен қолданылады, мұнда олардың жоғары жүк көтергіштігі және коррозияға төзімділігі оларды әртүрлі теңіз құрылымдарын салу үшін өте қолайлы етеді. Сонымен қатар, қазіргі заманғы сәулет жобаларында H секциялы арқалықтар көбінесе эстетикалық жағымды дизайн элементтері ретінде пайдаланылады, бұл заманауи құрылымдарға өнеркәсіптік әсер береді.

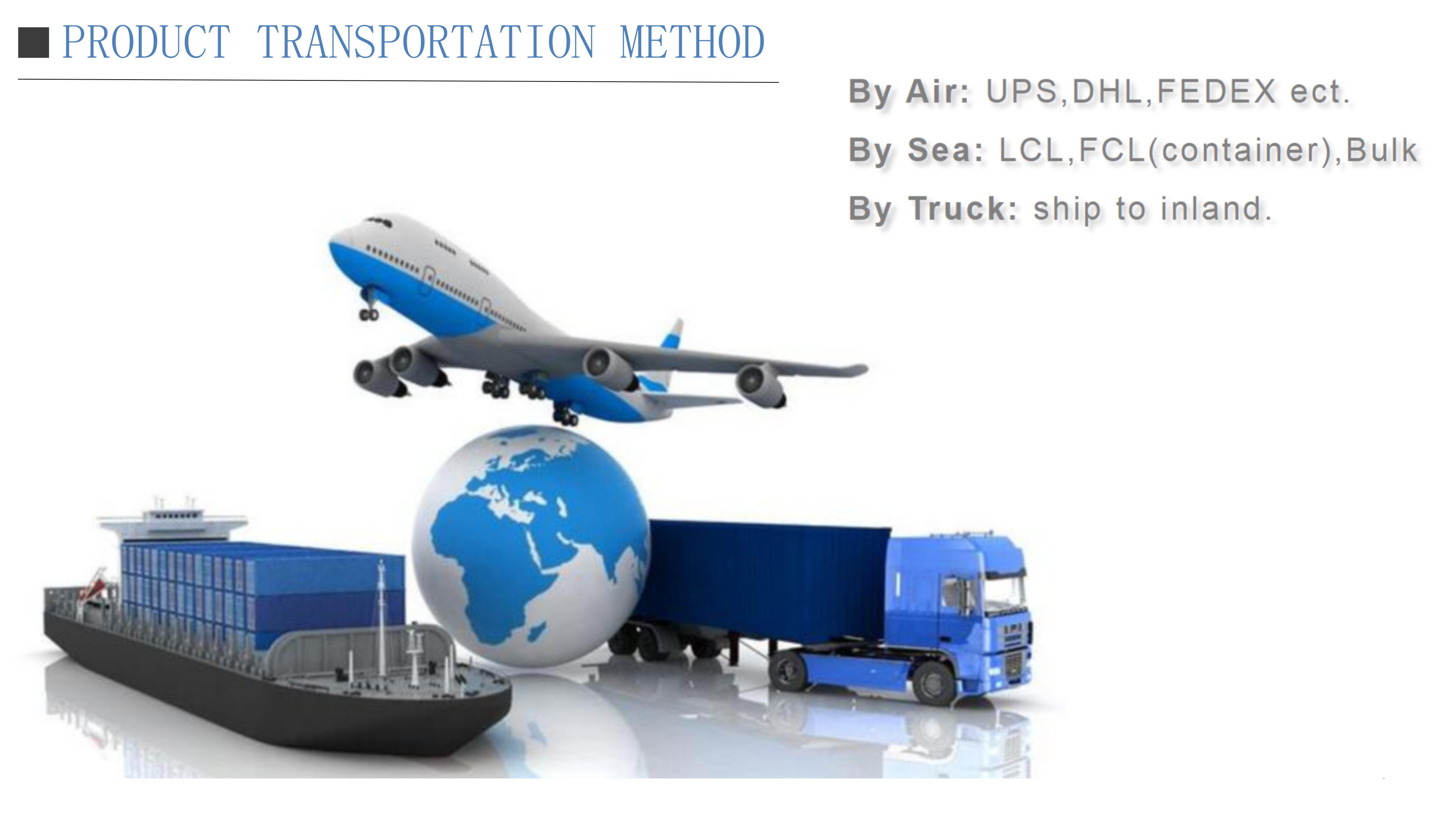

Қаптама және жеткізу

Қаптама:

Шпринт үйінділерін мықтап орналастырыңыз: H-арқалықты ұқыпты және тұрақты үйіндіге орналастырыңыз, олардың тұрақсыздықты болдырмау үшін дұрыс тураланғанына көз жеткізіңіз. Үйіндіні бекіту және тасымалдау кезінде жылжудың алдын алу үшін бауларды немесе таспаларды пайдаланыңыз.

Қорғаныш қаптама материалдарын пайдаланыңыз: Қағаз үйінділерінің жиынтығын судың, ылғалдың және басқа да қоршаған орта факторларының әсерінен қорғау үшін пластик немесе су өткізбейтін қағаз сияқты ылғалға төзімді материалмен ораңыз. Бұл тот пен коррозияның алдын алуға көмектеседі.

Жеткізілім:

Қолайлы тасымалдау түрін таңдаңыз: Шпунт үйінділерінің саны мен салмағына байланысты, тиісті тасымалдау түрін таңдаңыз, мысалы, платформалы жүк көліктері, контейнерлер немесе кемелер. Қашықтық, уақыт, құны және тасымалдауға қойылатын кез келген нормативтік талаптар сияқты факторларды ескеріңіз.

Тиісті көтергіш жабдықты пайдаланыңыз: U-тәрізді болат шпунт қадаларын тиеу және түсіру үшін крандар, жүк көтергіштер немесе тиегіштер сияқты тиісті көтергіш жабдықты пайдаланыңыз. Пайдаланылған жабдықтың шпунт қадаларының салмағын қауіпсіз көтеру үшін жеткілікті сыйымдылығы бар екеніне көз жеткізіңіз.

Жүкті бекітіңіз: Тасымалдау кезінде жылжуды, сырғанауды немесе құлауды болдырмау үшін қапталған шпунт үйінділерін тасымалдау көлігіне бекіткіштерді, бекіткіштерді немесе басқа да қолайлы құралдарды пайдаланып дұрыс бекітіңіз.

Жиі қойылатын сұрақтар

1. Сізден қалай баға ұсынысын ала аламын?

Сіз бізге хабарлама қалдыра аласыз, біз әрбір хабарламаға уақытында жауап береміз.

2. Тауарды уақытында жеткізесіз бе?

Иә, біз ең жақсы сапалы өнімдерді ұсынуға және уақытында жеткізуге уәде береміз. Адалдық - біздің компаниямыздың қағидасы.

3. Тапсырыс бермес бұрын үлгілерді ала аламын ба?

Иә, әрине. Әдетте біздің үлгілеріміз тегін, біз сіздің үлгілеріңіз немесе техникалық сызбаларыңыз бойынша жасай аламыз.

4. Төлем шарттары қандай?

Біздің әдеттегі төлем мерзімі - 30% депозит, ал қалғаны B/L. EXW, FOB, CFR, CIF.

5. Сіз үшінші тарап тексеруін қабылдайсыз ба?

Иә, міндетті түрде қабылдаймыз.

6. Біз сіздің компанияңызға қалай сенеміз?

Біз болат бизнесінде көп жылдар бойы алтын жеткізуші ретінде маманданғанбыз, штаб-пәтері Тяньцзинь провинциясында орналасқан, кез келген жолмен зерттеуге шақырамыз.